SciBase Journals

SciBase Clinical and Medical Case Reports

ISSN 2691-7785

- Article Type: Short Report

- Volume 1, Issue 1

- Received: Aug 11, 2023

- Accepted: Sep 08, 2023

- Published Online: Sep 15, 2023

New Cosmetic Carriers to Reduce Water Consumption and Waste

Pierfrancesco Morganti1,3*; Gianluca Morganti2

1R & D Center, Nanotechnology Unit, Academy of history of healthcare Art, Rome, Italy.

2ISCD Nanotechnology Centre, Rome, Italy.

3Dermatology Department China Medical University, Shenyang, China.

*Corresponding Author: Pierfrancesco Morganti

R & D Center, Nanotechnology Unit, Academy of history of healthcare Art, Rome, Italy.

Email: sakayline@gmail.com

Abstract

Beauty industry produces each year about 120 billion of packaging’units, 60% of which are made by plastic materials, invading the oceans as waste microparticles, toxic for animals and humans. Moreover, a great quantity of water is used to produce emulsions and solutions used as cosmetic carriers. Our research group are proposing smart patented non-woven tissues as alternative carriers for innovative medical devices, cosmeceuticals and nutraceuticals, reporting their main characteristics.

Keywords: Non-woven tissues; Cosmetic carriers; Chitin nanofibrils; Nanolignin diet supplements; Cosmeceuticals; Nutraceuticals; Waste; Water; Microplastics.

Citation: Morganti P, Morganti G. New Cosmetic Carriers to Reduce Water Consumption and Waste. SciBase Clin Med Case Rep. 2023; 1(1): 1002.

Introduction

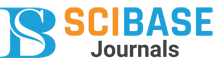

It has been estimated that personal care and beauty industry produce more than 120 billion units of packaging, most of which are not truly recyclable [1]. Also if the majority of the industries have in program to use more reusable, refilable or compostable biodegradable containers by 2025 [2], the beauty care and cosmetic products are actually a potential source of environmental contamination by microplastics, in a global cosmetic market that reached a value of about USD 326.4 in 2022 and expected to grow at a Compound Annual Growth Rate (CAGR) of 5.2% in the forecast period 2023-2028 [3,4]. At this purpose, it’s not to be forgotten the 82-358 trillion particles (mean 170 trillion) of the so-called microplastics which, weighting 1.1-4.9 million tonnes, are today afloating into the oceans [5]. Unfortunately they are considered food from fish and sea mammals and, entering into the human alimentary chain, have been recovered into cap-tea, placenta and human blood together with their content in toxic dangerous ingredients (Figure 1) [6-8].

Moreover to produce the majority of the beauty products, it is necessary to consume a great quantity of water, necessary to emulsify the oils for making emulsions and solutions, which represent the majority of the cosmetic carriers. In addition, the final product is enriched by fragrances and active ingredients and maintained free of microbes by preservatives and other chemicals, often cause of skin’ allergic reactions and sensitizing phenomena.

However, water is a key element for the formulation and manufacture of the cosmetic products which, ranging from about 60% for the creams to 80/90% for shampoo and solutions [9], are packed by plastic containers, 70% ending in landfills [10]. Thus the necessity to reduce water consumption trying to find alternative carriers and containers made by biodegradable polymers, as requested from scientists and consumers. The awareness of environmental damages, in fact, is steadily growing for years, thus becoming a collective eco-anxiety versus the oceans’ protection and preservation [11]. Therefore, it has been estimated that by 2050 the quantity of plastic by weight recovered into oceans will be more than the fish’ weight! [12].

Proposed solution

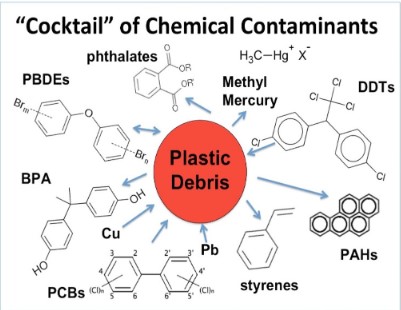

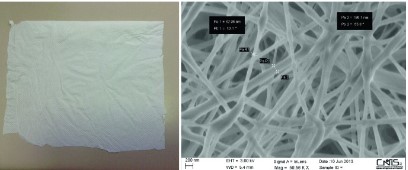

To reduce both consumption of water and production of plastic waste, our research group are proposing to substitute the actual cosmetic emulsion-carriers with various biodegradable non-woven tissues made by natural polymers, obtained from food and agro-forestry’s waste (Figure 2) [13,14]. The tissues’ activity and functions have been characterized by link the complex nanoparticles of Chitin Nanofibrils-Nanolignin (CN-LG) on the surface of their fibers by a patented process [15-17]. Moreover, the CN-LG micro/nanoparticles have been embedded by different active ingredients selected in function of the desired activity of the obtained medical devices,cosmeceuticals or nutraceuticals designed [18,19]. It is interesting to underline how the obtained tissues, having a structure similar to the natural Extra Cellular Matrix scaffold, may facilitate the penetration of the active ingredients through the different skin layers and cells (Figure 3) [20,21].

Conclusive remarks

Due to the consumer request for innovative products skin- and environmentally-friendly the use of these smart tissues, made by natural polymers, seems to go in the right direction. Produced by waste materials, they have shown to be effective as skin repairing activity. The recovered effectiveness of the designed tissues is probably due to the nanosize of the polymers used and the activity of the scaffold ECM-similar, obtained by the electrospinning technology used [22,23]. They, in fact, seem to possess the ability to transmit the biochemical signals necessary for the skin cell differentiation,attachment and growth [22,23].

In conclusion, the use of these smart tissue-carriers could represent an innovative and original solution to reduce not only the water consumption, but also to slow down the no more sustainable production and consumption of plastics used as packaging material.

Declarations

Author contributions: Idea of manuscript PM; writing-original draft preparation PM, GM; writing review and editing PM, GM; supervision PM. Both the authors have read and agree to the publishing version of manuscript.

Conflict of interest: The authors declare no conflict of interest.

References

- GVR. Cosmetic & Toiletry containers market size, share & trends analysis report by products, distribution channel, region and segment forecasts 2019-2025. Gran View Research Report, San Francisco, USA. 2023.

- Gatt IJ, Refalo P. Reusability and recyclability of plastic cosmetic packaging: A life cycle assessment, Resources, Conservation & Recycling Advances. 2022; 15: 200098.

- Bashir SM, Kimiko S, Mak CW, Fang JKH, Goncalves D. Personal care and cosmetic products as a potential source of environmental contamination by microplastics in a densely populated Asian city, Front Mar Sci. 2021; 8: 683482.

- EMR. Global Cosmetics Market Outlook 2023-2028, Exoert Market Reseach Report, Sheridan, WY, USA. 2023.

- Erikson M, Cowger W, Erdle LM, Coffin S, Villarubia-Gomez p, et al. A growing plastic-smog, now estimated to be over 170 trillion plastic particles afloat in the world’s oceans -urgent solutions required PLOS ONE. 2023; 3; 0281596.

- Hernandez LM, Xu EG, Larsson HCE, Tahara R, Mhisura VB and Tufenkji N. Plastic teabags release billions of microplastics and nanopartickes into tea, Environ Sci Technol. 2019; 53: 12300-12310.

- Ragusa A, Svelato A, Santacroce C, Catalano P, Notarstefano V, et al. Plasticenta: First evidence of microplastics in human placenta, Environment Int. 2021; 146: 106274.

- Leslie HA, an Velzen MJM, Brandsma SH, Vethaak AD, Garcia-Vallejo JJ, et al. Discover and quantification of plastic particle pollution in human blood, Env Int. 2022; 163: 1071199.

- Aguiar JB, Martins AM, Almeida C, Ribeiro HM, Margo J. Water sustainability: A waterless life cycle for cosmetic products. Sustainable Production and Consumption. 2022; 32: 35-51.

- Borunda A. The beauty industry generates a lot of plastic waste. Can it change ?. National Geopraphic Report. 2019.

- Brown P. Meeting beauty consumers where they are- and where they’re going, McKinsey & Company Report, New York, USA. 2023.

- MAF. P, astic in a Circular Economy, Ellen McArthur Foundstion Feport. 2016.

- Morganti P, Vannozzi A, Memic A, Coltelli MB. Chitin and lignin in the circular economy. In: P Morganti and MB Coltelli (Eds) An introduction to the circular economy, Nova Sciences Publishers, New York, USA. 2021; 281-296.

- Morganti P, Gao X, Vukovic N, Gagliardini A, Lohani A, et al. Food loss and food waste for green cosmetics and medical devices for a cleaner planet, Cosmetics. 2022; 9: 19.

- Morganti P, Gagliardini A, Morganti G. Nanochitin and nanolignin: Activity and effectiveness. In P. Morganti (Ed) Biofunctional textiles for an aging skin, Lambert Academjc Publishing, Chișinău, Republic of Moldova. 2022; 1: 405-449.

- Morganti P, Morganti G, Yudin VE, Chen HD . Chitin and lignin: old polymers and new bio-tissue-carriers, J Dermatology and Dermatitis. 2021: 6.

- Morganti P, Morganti G, Coltelli MB, Yudin VE, Chen HD, et al. Non-woven tissues as novel cosmetic carriers for a green beauty, Adv Environ Eng Res. 2022; 3: 2202221

- Morganti P, Morganti G, Memic A, Coltelli MB, Chen HD. The renaissance of beauty and wellness through the green economy, Latest Trendsin Textile & Fashion Design. 2021; 4: 04000185.

- Morganti P, Morganti G, Palombo M. Research and innovation for sustainable products:polysaccharides for a smart circular economy at zero waste, Auctores Publishing. 2021; 3: 037.

- Morganti P, Fusco A, Paoletti I, Perfetto B, Del Ciotto P, Palombo P, et al. Antiinflammatory. Immunomodulatory and Tissye Reosur Activity on Human Keratinocytes, Materials. 2017; 43.

- Danti S, Trombi L, Fusco A, Azimi B, Lazzari A, et al. Chitin nanofibrils and Nanolignin as functional agents in skin regeneration. Int J Mol Sci. 2019; 20: 2669.

- Morganti P and Coltelli MB. A new carrier for advanced cosmeceuticals, Cosmetics. 2019; 6: 10.

- Morganti P, Chen HD, Morganti G. Nanocosmetics: Future perspective . In: A Nanda, S Nanda, TA Nguyen, S Rajendran and Y Slimani (Eds) Nanocosmetics: Fundamentals, applications and toxicity, Elsevier, Amsterdam, Netherland. 2020; 455-481.